Description

Pointer Fixture: Precision, Quality, and Durability for Accurate Performance

A pointer fixture is a crucial tool used in various industries, particularly in automotive and industrial applications, for ensuring the accurate alignment and smooth operation of pointers, such as speedometer and gauge indicators. Whether you’re working with cars, clocks, or complex industrial machines, precision is key, and the pointer fixture provides that necessary accuracy.

In this comprehensive guide, we will delve deep into the features, benefits, and applications of pointer fixtures, as well as address some common questions that consumers might have regarding these valuable tools.

What is a Pointer Fixture?

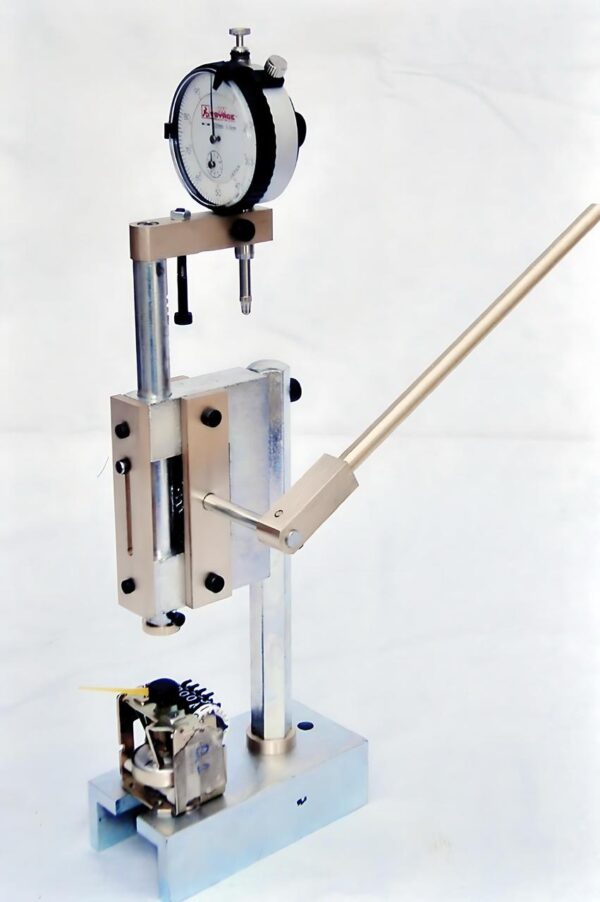

It is a mechanical tool designed to hold and adjust pointers in place, ensuring their accurate alignment during the manufacturing or repair process. These fixtures are often used in the production and assembly of speedometers, gauges, clocks, and other devices where precision is essential. Whether it’s a small dial on a watch or a large industrial gauge, the pointer fixture ensures that the pointer moves smoothly and provides accurate readings.

These are typically designed to be compatible with different types of pointers and measurement devices, making them versatile tools in the manufacturing and repair industries. The quality of the fixture determines how accurately and efficiently the pointer will perform its job, which makes selecting a high-quality fixture an important consideration.

Key Features

Pointer fixtures come with a variety of features to improve their performance and ease of use. Here are some of the most important features you’ll find in high-quality pointer fixtures:

-

Precision Engineering: The main purpose of it is to provide precision in aligning pointers. These fixtures are engineered to hold pointers in place with incredible accuracy, ensuring smooth and exact movement.

-

Durability: Most fixtures are made of high-grade materials like stainless steel or aluminum, making them durable enough to withstand the rigors of industrial environments. A durable pointer fixture ensures long-lasting performance and reliability.

-

Compatibility: Many fixtures are designed to be compatible with a variety of pointer types and devices. Whether you’re working with a car’s speedometer, an industrial gauge, or a clock, a good fixture will work seamlessly with the device.

-

Easy Setup: fixtures are typically designed for easy setup and operation. This saves time during the manufacturing or repair process, allowing professionals to get the job done quickly and accurately.

-

Adjustable Settings: Many fixtures come with adjustable settings to accommodate different types of pointers and devices. This feature adds versatility and flexibility to the tool, making it suitable for a wide range of applications.

Benefits of Using a Pointer Fixture

Using it offers several benefits, particularly in industries where accuracy and precision are essential. Here are some of the key advantages of using pointer fixtures:

-

Improved Accuracy: One of the primary benefits of using it is the improved accuracy it provides. By ensuring that the pointer is aligned properly, the fixture helps prevent errors in readings and measurements, leading to better overall performance.

-

Time-Saving: A fixture can save time during both the manufacturing and repair processes. Instead of manually adjusting pointers, which can be time-consuming and error-prone, the fixture holds the pointer securely in place, allowing for quick and easy adjustments.

-

Cost-Effective: By reducing errors and saving time, it can also reduce costs. Fewer mistakes mean less wasted material and fewer repairs or replacements, making the overall process more efficient and cost-effective.

-

Versatility: As mentioned earlier, fixtures are compatible with a wide range of devices, including automotive gauges, clocks, and industrial equipment. This versatility makes them an invaluable tool in various industries.

-

Enhanced Durability: High-quality pointer fixtures are built to last, ensuring long-term performance and reliability. Durable materials such as stainless steel or aluminum make these fixtures resistant to wear and tear, even in harsh industrial environments.

Applications

fixtures are used in a wide range of industries, from automotive manufacturing to clock making and industrial equipment assembly. Here are some of the most common applications of pointer fixtures:

-

Automotive Industry: In the automotive industry, pointer fixtures are used to ensure the accurate alignment of speedometer needles, fuel gauge pointers, and other indicators. Precision is critical in these applications, as even a small misalignment can lead to incorrect readings and potentially dangerous situations.

-

Clocks and Timepieces: In the production of clocks and watches, pointer fixtures help align the hands of the clock for accurate timekeeping. Even slight deviations in alignment can cause the clock to lose or gain time, so precision is essential.

-

Industrial Gauges: In industrial settings, gauges are used to measure pressure, temperature, and other variables. It ensure that these gauges are aligned properly, providing accurate readings that are essential for the safe and efficient operation of machinery.

-

Medical Devices: Certain medical devices, such as blood pressure monitors, also rely on accurate pointers to provide correct readings. Pointer fixtures help ensure that these devices function accurately and reliably.

-

Aerospace Industry: In the aerospace industry, precision is of utmost importance. fixtures are used to align the needles and indicators in aircraft cockpits, ensuring that pilots receive accurate information about altitude, speed, and other critical parameters.

Pointer Glowing Gauge

Pointer Glowing Gauge

Reviews

There are no reviews yet.